THE TEAM

John van der Kuur

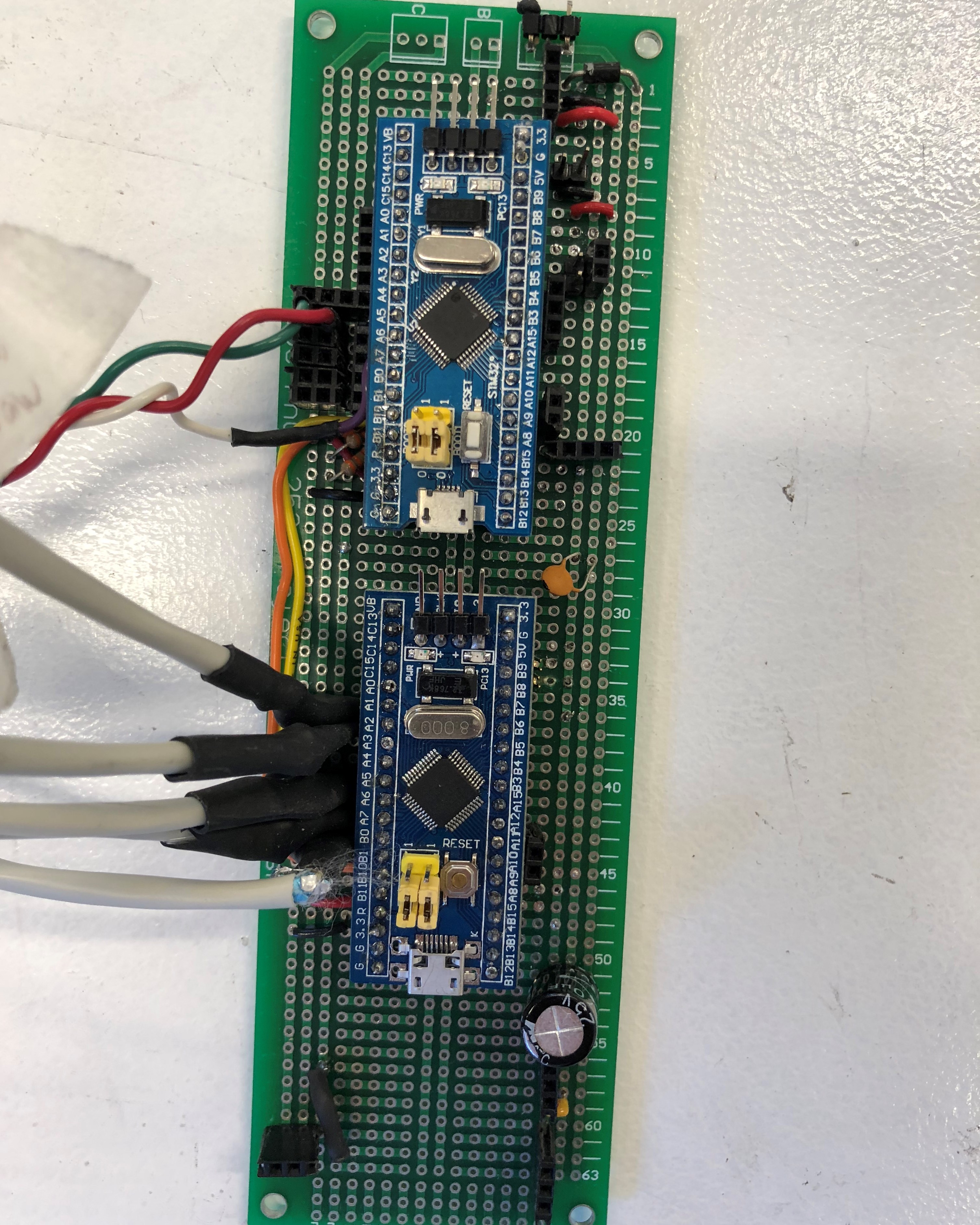

Software and Electronics

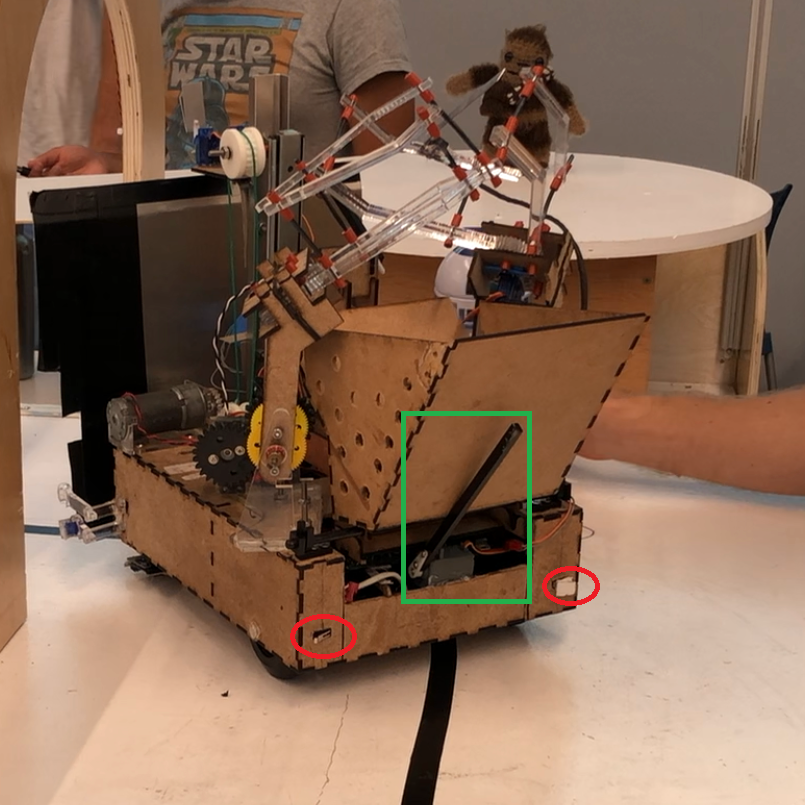

I am an engineering physics student with a keen interest in implementing software and electrical engineering. My main role on this robot was working with the microcontrollers to figure out the firmware including port manipulation and timer controls, communication between microcontrollers, and also a major contributor to the electrical circuit design/troubleshooting. Building this robot provided me with a newly discovered interest in low-level programming and firmware implementation, as well as electrical circuit design.

Jonah Gourlay

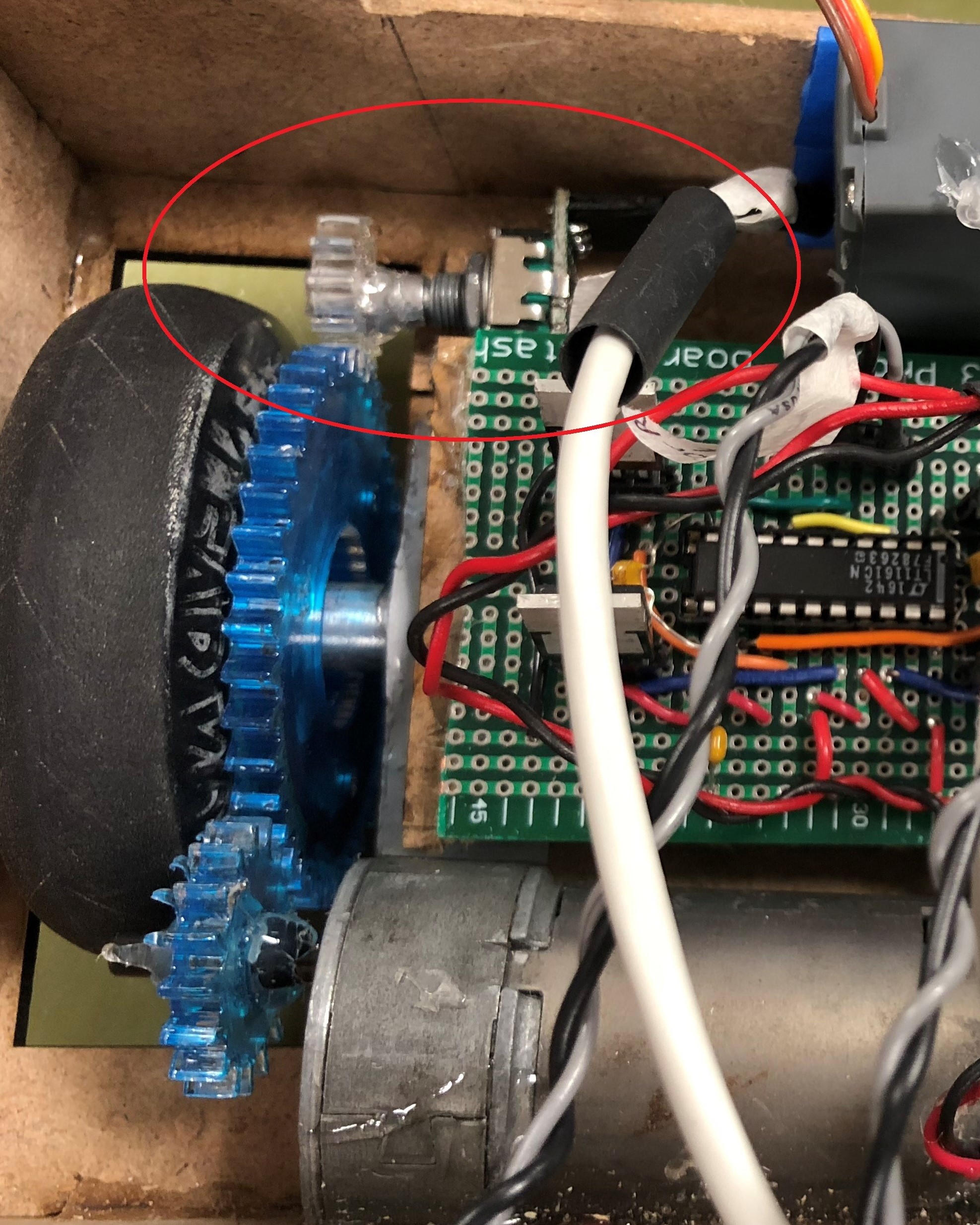

Mechanical Design

I am a third year engineering student at UBC with a passion for automotive engineering. I contributed largely to the overall mechanical design of the robot. I also built and installed both the IR circuit and bluetooth unto the robot. My experience over the summer has taught me a lot about mechanical design and troubleshooting electronics. This robot has given me a new found appreciation for the design process and the importance of design iteration. In my spare time I enjoy mountain biking, making my own music and collecting stamps.

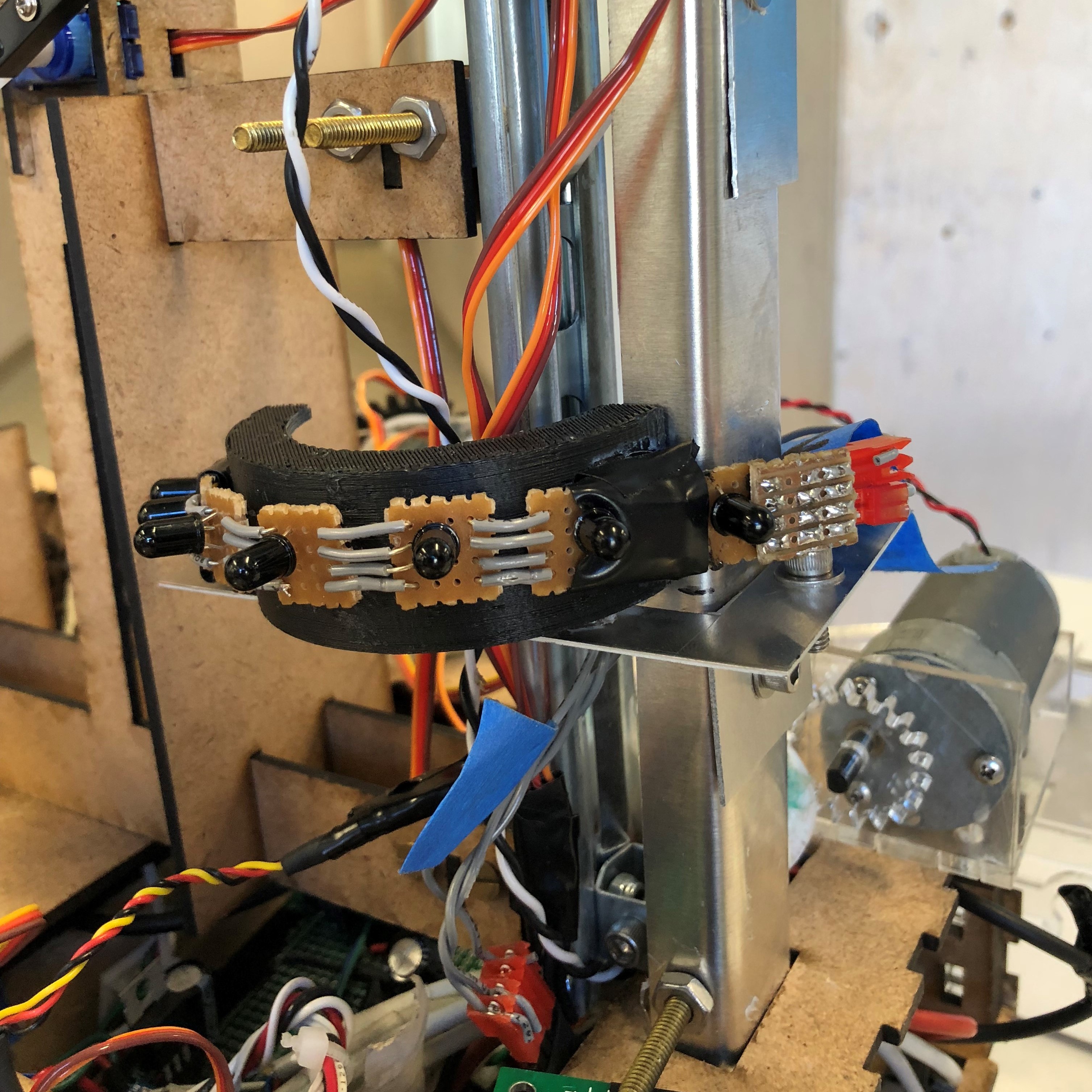

Daniel Backhouse

Mechanical Design

As a third-year engineering physics student with an interest in the applications of engineering in medicine, I spend my time outside of the classroom working at the Aging, Mobility and Cognitive Neurosciences Lab at Vancouver General Hospital and giving music therapy to older adults at a residential care facility in Richmond. My experiences working as a mechanical assistant for VR Avionics Canada helped in preparing for ENPH 253. In my spare time I like to stay active by boxing and have a keen interest in both cars and motorcycles.

Jeremy Wiens

Software and Electronics

This summer our team built an autonomous robot. I have been drawn to electronics and software development, so working on STEV-E provided a unique opportunity to further explore these aspects in a practical, hands-on way. My responsibilities included writing the state-machine and PID code, designing a menu system, and creating a H-bridge circuit. Working with a team to meet a challenging deadline not only helped me improve my programming and troubleshooting abilities but also fine-tuned my leadership and problem-solving skills.